Why Water Circulation is Crucial for Chiller Efficiency?

Why Water Circulation is Crucial for Chiller Efficiency?

This article delves into why water must be circulated through a water chiller and the significant impact it has on chiller efficiency. You will benefit from understanding how proper water circulation enhances heat transfer, prevents overheating, and optimizes energy use, ultimately prolonging the chiller’s lifespan and reducing operational costs.

Key Points

- Proper water circulation is vital for chiller efficiency

- Increasing water flow rate enhances chiller performance

- Preventing equipment overheating ensures longevity

- Water flow rate impacts chiller performance significantly

- Inadequate water circulation leads to operational issues

- Maintenance tips are crucial for optimal water circulation

How Water Circulation Affects Chiller Efficiency?

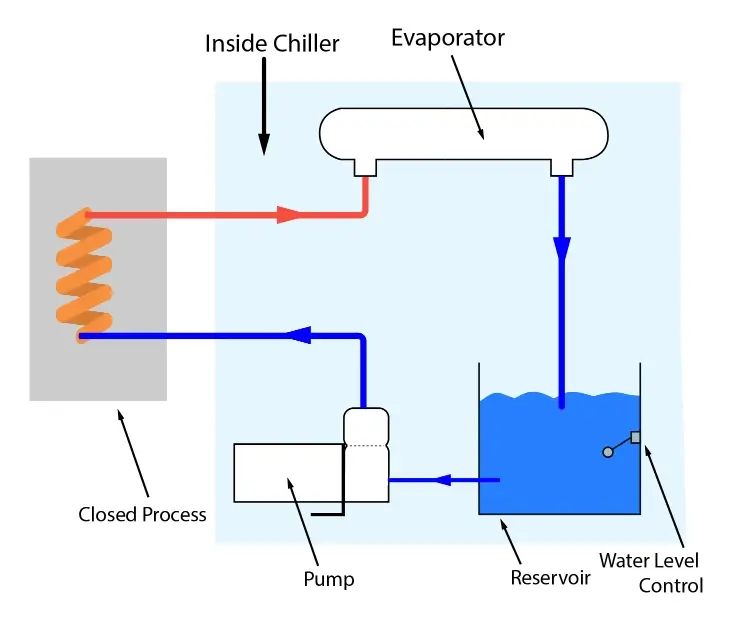

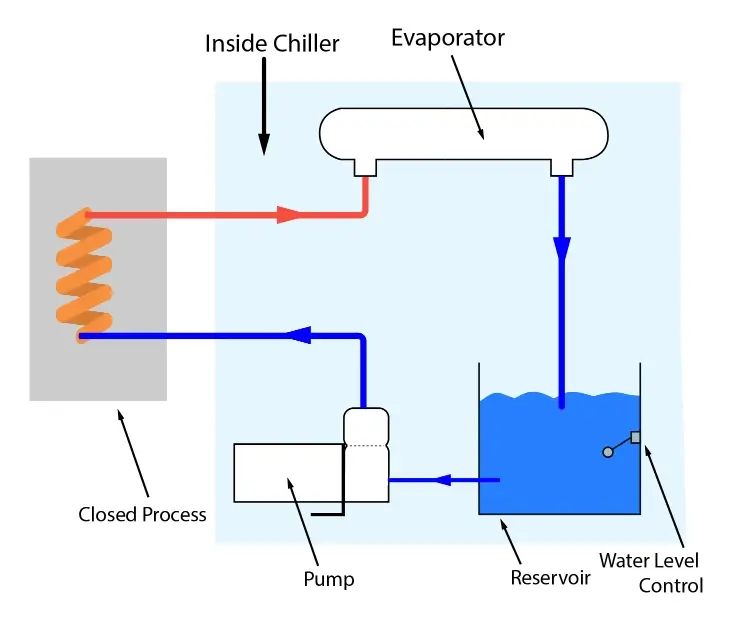

Water chillers function at the precept of heat alternate, wherein water acts because the number one medium to soak up heat from the environment or process it’s miles cooling. This absorbed warmness is then transferred to the chiller’s cooling machine in which it’s far expelled, generally to the outdoor air.

The efficiency of this warmth switch system closely is predicated at the rate at which water is circulated via the chiller. A right glide charge ensures that warmth is correctly absorbed and removed, stopping the machine from overheating and reducing the power required to hold the favored temperature. This is a key consideration in each the design and operation of chiller systems.

| Water waft fee (GPM) | Chiller performance (% growth) | Warmth transfer rate (BTU/hr) |

| 100 | 85% | 500,000 |

| 200 | 95% | 1,000,000 |

| 300 | 98% | 1,500,000 |

As illustrated inside the table above, increasing the water glide rate can substantially enhance the chiller’s performance. That is because greater water circulating via the system means more heat can be transferred in line with unit of time. Therefore, keeping the proper waft charge isn’t just a be counted of operational balance but also of strength efficiency and price-effectiveness.

It is important to display and preserve the glide rate as consistent with the chiller’s design specs. Deviations from these specs can cause inefficiencies, as both too low or too high a waft fee can negatively effect the machine’s ability to efficiently manipulate heat. Low water float quotes lead to insufficient warmth absorption, inflicting the chiller to work tougher and use more strength, at the same time as excessively high flow charges can cause erosion and premature wear inside the piping and gadget.

In conclusion, keeping proper water stream inside a chiller is critical for maximizing efficiency, optimizing energy use, and prolonging the lifespan of the gadget. Normal tests and balances, as outlined in upkeep schedules, are imperative to make sure the system operates at its satisfactory.

The Role of Water in Heat Exchange Processes within Chillers

As a medium, water’s excessive particular warmness potential makes it exceptionally effective at absorbing and transporting warmness. In chillers, water is used to carry warmth faraway from the system’s compressor, that’s critical to keep the performance and capability of the chilling cycle.

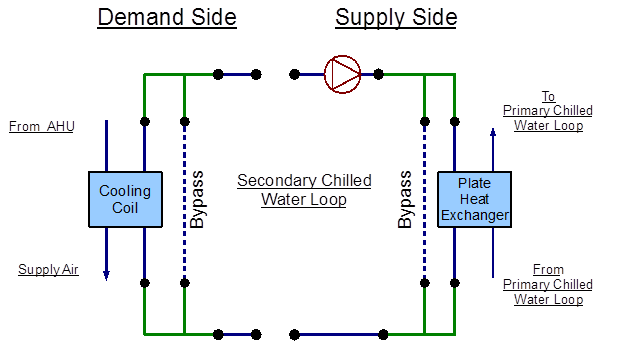

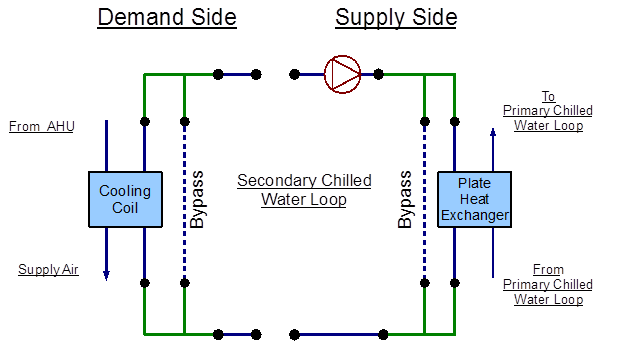

Inside the warmth trade method, water is circulated through a closed circuit within the chiller. It first absorbs the warmth generated via the compressor. This heated water then travels to a condenser, where it releases the heat to the surrounding surroundings, usually the air or a secondary water line in larger systems. The cooled water is then recirculated returned to soak up more warmth, continuing the cycle.

This continuous drift of water ensures that the chiller operates at most desirable temperatures and prevents the machine from overheating. powerful water move is crucial for preserving the efficiency of this technique, as any disruption within the flow can result in an boom in temperature, which in turn, reduces the chiller’s performance and can potentially reason equipment failure due to overheating.

The performance of the warmth exchange system is at once stimulated through numerous factors, which include water purity, drift rate, and the bodily properties of the gadget additives. Any modifications in these parameters can notably affect the chiller’s potential to perform its capabilities successfully. Consequently, preserving right water exceptional and go with the flow through the device is vital for sustaining most appropriate operational conditions.

Moreover, the heat trade performance also can be optimized by means of adjusting the fee at which water is circulated through the chiller. A higher waft rate usually improves warmness transfer performance, however also calls for more energy for water circulate. As a result, accomplishing a stability between efficient warmth transfer and electricity consumption is fundamental to designing and running chiller systems efficaciously.

Preventing Equipment Overheating and Ensuring Longevity

Water chillers are designed to put off warmth from methods or conditioning structures through shifting this warmth to the water. With out good enough move, the warmth transfer manner will become inefficient, leading to increased temperatures that may purpose untimely gadget failure.

consistent water flow aids within the stable and powerful dissipation of heat. It guarantees that the temperature of the cooling medium stays inside designed operational limits, thereby safeguarding sensitive additives including compressors, evaporators, and condensers. This safety in opposition to overheating isn’t simplest vital for preserving chiller performance however also extends the lifespan of the system with the aid of lowering thermal strain.

additionally, adequate water float allows in averting hot spots inside the chiller unit. These hot spots can result in the formation of scale and corrosion, which detrimentally impact the performance and durability of the chiller. Ensuring a uniform temperature distribution and consistent water chemistry minimizes those dangers, thereby preserving the integrity of the chiller’s inner surfaces.

| Factor | Function | Effect of Overheating |

| Compressor | Compresses the refrigerant and circulates it through the gadget. | better operating temperatures can result in mechanical failures and lubrication breakdown. |

| Evaporator | Absorbs warmth from the method or area being cooled. | Scaling and fouling can arise, lowering heat switch performance and growing electricity intake. |

| Condenser | Releases absorbed warmness to the water being circulated. | inadequate cooling can motive the condenser to function above its capacity, leading to ability shutdowns and maintenance. |

It’s miles evident that retaining an finest water movement rate isn’t always simply a depend of overall performance efficiency but is essential for stopping downtime and extending the operational life of the chiller. Regular tracking and upkeep of the water glide price have to be an necessary a part of any chiller device management plan to make sure those targets are met.

Impact of Water Flow Rate on Chiller Performance

Right stream of water guarantees that warmth alternate within the chiller gadget occurs efficiently. An wrong go with the flow price can lead to numerous problems that compromise the system’s effectiveness and durability.

At an premier float fee, the water can correctly soak up warmth from the chiller’s condenser, for this reason maintaining the favored temperature control. If the water flow is simply too low, it could no longer soak up enough warmth, inflicting the chiller to work tougher than essential. This no longer most effective will increase electricity consumption however additionally leads to extended put on and tear on the chiller components.

Conversely, a waft water this is too excessive also can be destructive. Even though it may seem beneficial for warmth switch, an excessively high float charge can lessen the overall warmth switch efficiency due to reduced house time of water in the machine. This speedy flow can save you the water from achieving sufficient warmth absorption, leading to inefficiencies.

moreover, preserving the correct water float price is imperative for stopping problems which includes chiller surge, which happens while the chiller operates under its potential due to inadequate load. This will reason fluctuations in stress and temperature, main to capacity harm and reduced reliability of the chiller machine.

it is also important to monitor and alter the glide price to ensure that it aligns with the chiller’s specs and the operational demands of the wider HVAC gadget. Variations in load necessities or external temperature adjustments can necessitate adjustments in drift fee to keep surest efficiency and overall performance of the chiller.

Common Issues with Inadequate Water Circulation in Chillers

Insufficient water flow in chiller structures can result in a myriad of operational challenges. These troubles no longer handiest have an effect on the performance of the chiller however also can compromise the device’s toughness and reliability. Spotting these not unusual problems is essential for keeping most fulfilling performance.

Decreased heat transfer efficiency

One of the number one issues due to inadequate water glide is reduced warmth switch performance. Chillers depend upon the consistent go with the flow of water to cast off warmth from the device successfully. Whilst water circulation is insufficient, the significant degradation of heat exchanger performance, main to bad chiller performance and elevated power consumption.

Increased operating costs

With reduced efficiency, chillers have to paintings harder and longer to gain the same cooling impact, which in turn, drives up energy intake. The accelerated operational stress not most effective results in higher energy bills however additionally escalates preservation fees because of extra common maintenance and component replacements.

Chance of device Overheating

Some other critical issue stemming from insufficient water flow is the danger of equipment overheating. With out enough water float, the chiller can’t use up warmth efficiently. This overheating can cause giant harm to crucial additives such as compressors and warmth exchangers, probably leading to machine failure.

Formation of Scale and Corrosion

Terrible water waft also can encourage the formation of scale and sell corrosion inside the chiller. These problems are often exacerbated with the aid of inconsistent water speeds, which permit minerals to deposit and corrode the internal surfaces, further lowering the system’s performance and lifespan.

| Problem | Consequences |

| decreased heat transfer | lower cooling performance, accelerated strength consumption |

| improved Operational costs | better electricity and maintenance prices |

| equipment Overheating | ability system failure, damage to additives |

| Scale and Corrosion | reduced machine lifespan, similarly efficiency losses |

System Imbalance

Lack of ok water drift can also cause an imbalance in the distribution of cooled water, main to inconsistent cooling performance across the gadget. This imbalance not best affects precise areas being cooled less efficiently however can also strain different elements of the chiller as they make amends for the disparity.

Manipulate and Sensor screw ups

Sooner or later, inadequate water move can intrude with the proper functioning of controls and sensors inside the chiller system. Those components rely upon specific waft charges to perform correctly; deviations can result in fake readings or malfunctions, similarly impairing the chiller’s operation and safety.

Addressing these problems requires normal preservation exams, right device layout, and immediate attention to any signs of bad water circulation. Via making sure most beneficial water go with the flow thru the chiller, one could keep its efficiency, make bigger its operational existence, and decrease universal fees.

Maintenance Tips for Optimal Water Circulation in Chiller Systems

Making sure most efficient water circulation in chiller systems is critical for maintaining performance and extending the lifespan of the device. Normal preservation of the water circulation additives not simplest enhances performance but also prevents capacity screw ups that could result in steeply-priced downtime and maintenance.

Regular Inspection and cleaning of Water Circuits

It’s miles vital to regularly check out and easy the water circuits inside the chiller device. Accumulation of particles and scaling can notably obstruct water drift, decreasing the performance of heat exchange and growing strength intake. Scheduled cleanings assist hold the integrity of the water circuit and make certain steady and effective water drift.

Monitoring Water go with the flow costs

Preserving a watch on water go with the flow prices is critical. There should be a balance; too low a drift price leads to inadequate cooling and viable chiller overheating, even as too excessive a flow price can cause immoderate wear and tear on the system components.

Checking and Adjusting Water Chemistry

Water chemistry plays a sizable position in the operation of chiller systems. Bad water pleasant can cause corrosion, scaling, and biological boom, all of which could hinder the gadget’s performance and durability. Normal testing and remedy of the water supply are vital to keep an appropriate chemical stability and prevent these problems.

Making sure proper Pump capability

The pump is a core element of the chiller’s water move device. Ensuring its proper capability is vital for maintaining powerful water glide via the chiller. Ordinary checks for wear and tear, lubrication, and operational performance ought to be a part of the preservation schedule.

| Upkeep activity | Frequency | Impact |

| Cleaning of water circuits | Yearly or as needed | Prevents blockages and continues drift efficiency |

| Tracking water drift quotes | Continuous with periodic assessments | Guarantees most efficient cooling and gadget health |

| Water chemistry adjustment | Quarterly | Prevents scaling, corrosion, and organic increase |

| Pump inspection and renovation | Semi-yearly | ensures effective water circulate |

Keeping a chiller system calls for a proactive technique to water stream management. By way of following those recommendations, operators can make certain efficient machine performance, minimize operational prices, and enlarge the beneficial existence of the gadget.

Harman N’s wants all ice bath enthusiasts to have more fun on a limited budget.

Fill out your contact information to explore the best ice bath options for you with a Harman N’s manager!

Vestibulum ante ipsum

You also want to know these…

Vestibulum ante ipsum

Why Water Circulation is Crucial for Chiller Efficiency?

This article delves into why water must be circulated through a water chiller and the significant impact it has on chiller efficiency. You will benefit from understanding how proper water circulation enhances heat transfer, prevents overheating, and optimizes energy use, ultimately prolonging the chiller’s lifespan and reducing operational costs.

Key Points

- Proper water circulation is vital for chiller efficiency

- Increasing water flow rate enhances chiller performance

- Preventing equipment overheating ensures longevity

- Water flow rate impacts chiller performance significantly

- Inadequate water circulation leads to operational issues

- Maintenance tips are crucial for optimal water circulation

How Water Circulation Affects Chiller Efficiency?

Water chillers function at the precept of heat alternate, wherein water acts because the number one medium to soak up heat from the environment or process it’s miles cooling. This absorbed warmness is then transferred to the chiller’s cooling machine in which it’s far expelled, generally to the outdoor air.

The efficiency of this warmth switch system closely is predicated at the rate at which water is circulated via the chiller. A right glide charge ensures that warmth is correctly absorbed and removed, stopping the machine from overheating and reducing the power required to hold the favored temperature. This is a key consideration in each the design and operation of chiller systems.

| Water waft fee (GPM) | Chiller performance (% growth) | Warmth transfer rate (BTU/hr) |

| 100 | 85% | 500,000 |

| 200 | 95% | 1,000,000 |

| 300 | 98% | 1,500,000 |

As illustrated inside the table above, increasing the water glide rate can substantially enhance the chiller’s performance. That is because greater water circulating via the system means more heat can be transferred in line with unit of time. Therefore, keeping the proper waft charge isn’t just a be counted of operational balance but also of strength efficiency and price-effectiveness.

It is important to display and preserve the glide rate as consistent with the chiller’s design specs. Deviations from these specs can cause inefficiencies, as both too low or too high a waft fee can negatively effect the machine’s ability to efficiently manipulate heat. Low water float quotes lead to insufficient warmth absorption, inflicting the chiller to work tougher and use more strength, at the same time as excessively high flow charges can cause erosion and premature wear inside the piping and gadget.

In conclusion, keeping proper water stream inside a chiller is critical for maximizing efficiency, optimizing energy use, and prolonging the lifespan of the gadget. Normal tests and balances, as outlined in upkeep schedules, are imperative to make sure the system operates at its satisfactory.

The Role of Water in Heat Exchange Processes within Chillers

As a medium, water’s excessive particular warmness potential makes it exceptionally effective at absorbing and transporting warmness. In chillers, water is used to carry warmth faraway from the system’s compressor, that’s critical to keep the performance and capability of the chilling cycle.

Inside the warmth trade method, water is circulated through a closed circuit within the chiller. It first absorbs the warmth generated via the compressor. This heated water then travels to a condenser, where it releases the heat to the surrounding surroundings, usually the air or a secondary water line in larger systems. The cooled water is then recirculated returned to soak up more warmth, continuing the cycle.

This continuous drift of water ensures that the chiller operates at most desirable temperatures and prevents the machine from overheating. powerful water move is crucial for preserving the efficiency of this technique, as any disruption within the flow can result in an boom in temperature, which in turn, reduces the chiller’s performance and can potentially reason equipment failure due to overheating.

The performance of the warmth exchange system is at once stimulated through numerous factors, which include water purity, drift rate, and the bodily properties of the gadget additives. Any modifications in these parameters can notably affect the chiller’s potential to perform its capabilities successfully. Consequently, preserving right water exceptional and go with the flow through the device is vital for sustaining most appropriate operational conditions.

Moreover, the heat trade performance also can be optimized by means of adjusting the fee at which water is circulated through the chiller. A higher waft rate usually improves warmness transfer performance, however also calls for more energy for water circulate. As a result, accomplishing a stability between efficient warmth transfer and electricity consumption is fundamental to designing and running chiller systems efficaciously.

Preventing Equipment Overheating and Ensuring Longevity

Water chillers are designed to put off warmth from methods or conditioning structures through shifting this warmth to the water. With out good enough move, the warmth transfer manner will become inefficient, leading to increased temperatures that may purpose untimely gadget failure.

consistent water flow aids within the stable and powerful dissipation of heat. It guarantees that the temperature of the cooling medium stays inside designed operational limits, thereby safeguarding sensitive additives including compressors, evaporators, and condensers. This safety in opposition to overheating isn’t simplest vital for preserving chiller performance however also extends the lifespan of the system with the aid of lowering thermal strain.

additionally, adequate water float allows in averting hot spots inside the chiller unit. These hot spots can result in the formation of scale and corrosion, which detrimentally impact the performance and durability of the chiller. Ensuring a uniform temperature distribution and consistent water chemistry minimizes those dangers, thereby preserving the integrity of the chiller’s inner surfaces.

| Factor | Function | Effect of Overheating |

| Compressor | Compresses the refrigerant and circulates it through the gadget. | better operating temperatures can result in mechanical failures and lubrication breakdown. |

| Evaporator | Absorbs warmth from the method or area being cooled. | Scaling and fouling can arise, lowering heat switch performance and growing electricity intake. |

| Condenser | Releases absorbed warmness to the water being circulated. | inadequate cooling can motive the condenser to function above its capacity, leading to ability shutdowns and maintenance. |

It’s miles evident that retaining an finest water movement rate isn’t always simply a depend of overall performance efficiency but is essential for stopping downtime and extending the operational life of the chiller. Regular tracking and upkeep of the water glide price have to be an necessary a part of any chiller device management plan to make sure those targets are met.

Impact of Water Flow Rate on Chiller Performance

Right stream of water guarantees that warmth alternate within the chiller gadget occurs efficiently. An wrong go with the flow price can lead to numerous problems that compromise the system’s effectiveness and durability.

At an premier float fee, the water can correctly soak up warmth from the chiller’s condenser, for this reason maintaining the favored temperature control. If the water flow is simply too low, it could no longer soak up enough warmth, inflicting the chiller to work tougher than essential. This no longer most effective will increase electricity consumption however additionally leads to extended put on and tear on the chiller components.

Conversely, a waft water this is too excessive also can be destructive. Even though it may seem beneficial for warmth switch, an excessively high float charge can lessen the overall warmth switch efficiency due to reduced house time of water in the machine. This speedy flow can save you the water from achieving sufficient warmth absorption, leading to inefficiencies.

moreover, preserving the correct water float price is imperative for stopping problems which includes chiller surge, which happens while the chiller operates under its potential due to inadequate load. This will reason fluctuations in stress and temperature, main to capacity harm and reduced reliability of the chiller machine.

it is also important to monitor and alter the glide price to ensure that it aligns with the chiller’s specs and the operational demands of the wider HVAC gadget. Variations in load necessities or external temperature adjustments can necessitate adjustments in drift fee to keep surest efficiency and overall performance of the chiller.

Common Issues with Inadequate Water Circulation in Chillers

Insufficient water flow in chiller structures can result in a myriad of operational challenges. These troubles no longer handiest have an effect on the performance of the chiller however also can compromise the device’s toughness and reliability. Spotting these not unusual problems is essential for keeping most fulfilling performance.

Decreased heat transfer efficiency

One of the number one issues due to inadequate water glide is reduced warmth switch performance. Chillers depend upon the consistent go with the flow of water to cast off warmth from the device successfully. Whilst water circulation is insufficient, the significant degradation of heat exchanger performance, main to bad chiller performance and elevated power consumption.

Increased operating costs

With reduced efficiency, chillers have to paintings harder and longer to gain the same cooling impact, which in turn, drives up energy intake. The accelerated operational stress not most effective results in higher energy bills however additionally escalates preservation fees because of extra common maintenance and component replacements.

Chance of device Overheating

Some other critical issue stemming from insufficient water flow is the danger of equipment overheating. With out enough water float, the chiller can’t use up warmth efficiently. This overheating can cause giant harm to crucial additives such as compressors and warmth exchangers, probably leading to machine failure.

Formation of Scale and Corrosion

Terrible water waft also can encourage the formation of scale and sell corrosion inside the chiller. These problems are often exacerbated with the aid of inconsistent water speeds, which permit minerals to deposit and corrode the internal surfaces, further lowering the system’s performance and lifespan.

| Problem | Consequences |

| decreased heat transfer | lower cooling performance, accelerated strength consumption |

| improved Operational costs | better electricity and maintenance prices |

| equipment Overheating | ability system failure, damage to additives |

| Scale and Corrosion | reduced machine lifespan, similarly efficiency losses |

System Imbalance

Lack of ok water drift can also cause an imbalance in the distribution of cooled water, main to inconsistent cooling performance across the gadget. This imbalance not best affects precise areas being cooled less efficiently however can also strain different elements of the chiller as they make amends for the disparity.

Manipulate and Sensor screw ups

Sooner or later, inadequate water move can intrude with the proper functioning of controls and sensors inside the chiller system. Those components rely upon specific waft charges to perform correctly; deviations can result in fake readings or malfunctions, similarly impairing the chiller’s operation and safety.

Addressing these problems requires normal preservation exams, right device layout, and immediate attention to any signs of bad water circulation. Via making sure most beneficial water go with the flow thru the chiller, one could keep its efficiency, make bigger its operational existence, and decrease universal fees.

Maintenance Tips for Optimal Water Circulation in Chiller Systems

Making sure most efficient water circulation in chiller systems is critical for maintaining performance and extending the lifespan of the device. Normal preservation of the water circulation additives not simplest enhances performance but also prevents capacity screw ups that could result in steeply-priced downtime and maintenance.

Regular Inspection and cleaning of Water Circuits

It’s miles vital to regularly check out and easy the water circuits inside the chiller device. Accumulation of particles and scaling can notably obstruct water drift, decreasing the performance of heat exchange and growing strength intake. Scheduled cleanings assist hold the integrity of the water circuit and make certain steady and effective water drift.

Monitoring Water go with the flow costs

Preserving a watch on water go with the flow prices is critical. There should be a balance; too low a drift price leads to inadequate cooling and viable chiller overheating, even as too excessive a flow price can cause immoderate wear and tear on the system components.

Checking and Adjusting Water Chemistry

Water chemistry plays a sizable position in the operation of chiller systems. Bad water pleasant can cause corrosion, scaling, and biological boom, all of which could hinder the gadget’s performance and durability. Normal testing and remedy of the water supply are vital to keep an appropriate chemical stability and prevent these problems.

Making sure proper Pump capability

The pump is a core element of the chiller’s water move device. Ensuring its proper capability is vital for maintaining powerful water glide via the chiller. Ordinary checks for wear and tear, lubrication, and operational performance ought to be a part of the preservation schedule.

| Upkeep activity | Frequency | Impact |

| Cleaning of water circuits | Yearly or as needed | Prevents blockages and continues drift efficiency |

| Tracking water drift quotes | Continuous with periodic assessments | Guarantees most efficient cooling and gadget health |

| Water chemistry adjustment | Quarterly | Prevents scaling, corrosion, and organic increase |

| Pump inspection and renovation | Semi-yearly | ensures effective water circulate |

Keeping a chiller system calls for a proactive technique to water stream management. By way of following those recommendations, operators can make certain efficient machine performance, minimize operational prices, and enlarge the beneficial existence of the gadget.

Harman N’s wants all ice bath enthusiasts to have more fun on a limited budget.

Fill out your contact information to explore the best ice bath options for you with a Harman N’s manager!

Vestibulum ante ipsum

You also want to know these…

About ther Author

Welcome to our blog! My name is peter and I am the lead author of this blog. As a sport recovery practitioner and with deep interests and expertise.

I am committed to presenting complex concepts in a clear and concise manner, and enabling readers to better understand and apply that knowledge through in-depth research and experience sharing.

Thank you for reading and for your support! If you have questions or suggestions about any of the content, please feel free to contact me. I look forward to sharing more interesting and useful information with you and growing together on this journey of knowledge!