Wat zijn de drie soorten koelmachines?

Wat zijn de drie soorten koelmachines?

Wat zijn de drie soorten koelmachines?

Explores the different types of chillers—air-cooled, water-cooled, En absorption chillers—highlighting their unique features, applications, and maintenance requirements. Air-cooled chillers are praised for their easy installation and low cost, making them ideal for commercial buildings with limited space. Water-cooled chillers, known for their high efficiency, are suitable for larger installations but require more maintenance.

Air-Cooled Chillers: Key Features and Benefits

De air-cooled chillers offer numerous distinct advantages. These systems are especially renowned for their ease of installment and lower initial costs compared to various other sorts of chillers. Air-cooled chillers do not need a separate cooling tower, which simplifies their setup and upkeep. This function alone makes them a perfect choice for installations where water sources are minimal or where extra infrastructure is not possible.

Among the vital benefits of air-cooled chillers is their adaptability. They can be mounted both inside your home and outdoors, offering flexible application in numerous atmospheres. Typisch, air-cooled chillers are used in business buildings, information facilities, and industrial procedures where area goes to a costs. Their compact layout and capability to operate in a wide variety of temperatures further enhance their appeal.

In regards to performance, air-cooled chillers are outfitted with advanced cooling innovations that ensure reliable procedure. Modern devices typically include variable speed drives (VSD) and microchannel condenser coils, which assist to make best use of power performance and reduce operational prices. Aanvullend, these chillers are designed with durable parts that give reputable performance over extended periods, reducing the demand for constant maintenance.

| Attribute | Advantage |

|---|---|

| Ease of Installation | No need for cooling down tower, simpler configuration |

| Flexibility | Can be mounted inside or outdoors |

| Advanced Cooling Technologies | Greater energy performance, reduced operational costs |

| Robust Components | Reliable performance, reduced maintenance |

On the whole, the essential attributes and benefits of air-cooled refrigerators make them a highly appealing choice for numerous applications. Whether handling restrictions associated with room, water availability, or budget, these chillers offer a flexible and economical option for cooling down requirements.

Water-Cooled Chillers: Efficiency and Applications

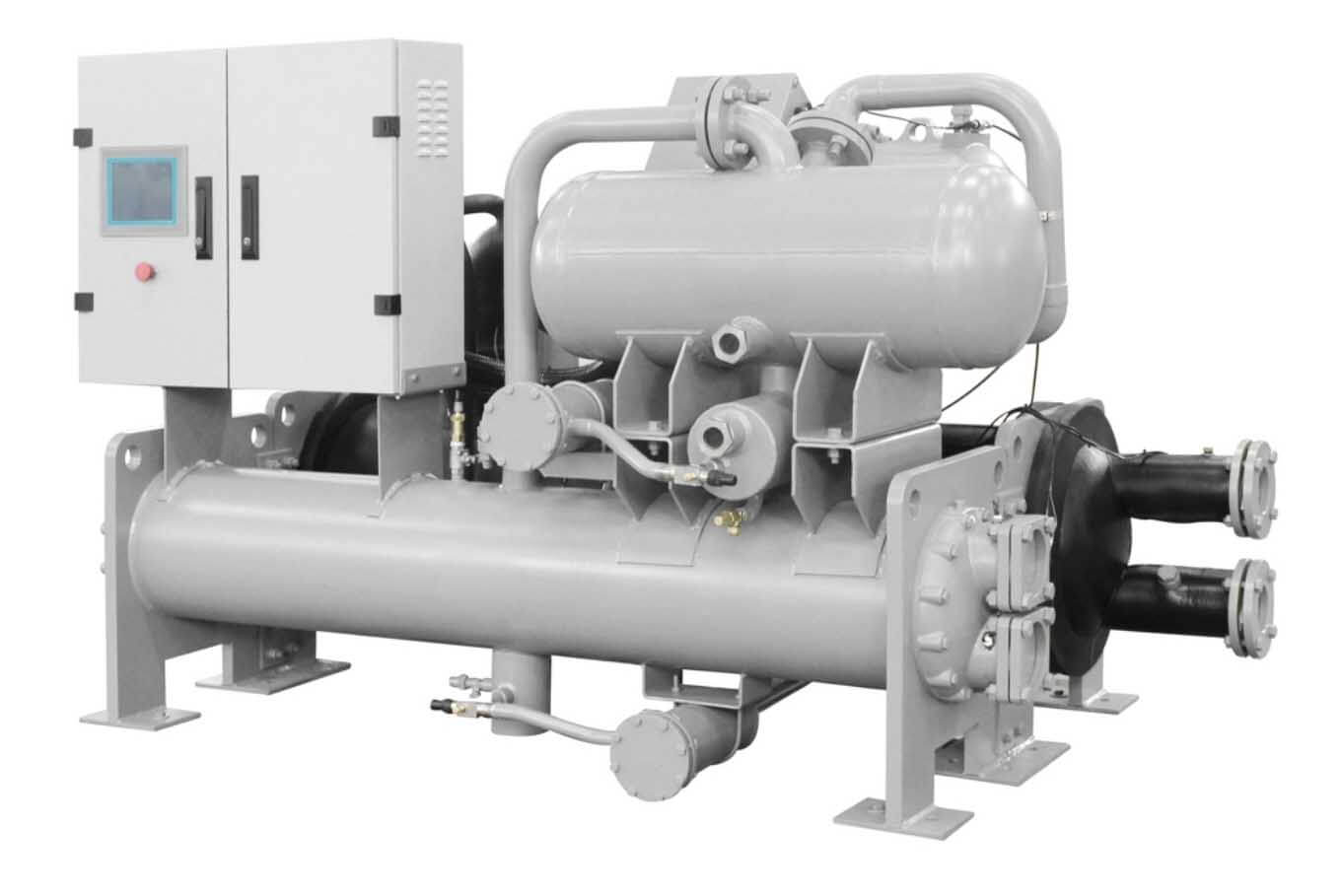

Water-cooled chillers are known for their high effectiveness and are commonly used in larger commercial and industrial setups. These systems utilize water from an outside air conditioning tower to dissipate warm, making them much more effective than air-cooled chillers in a lot of instances. The primary benefit of water-cooled chillers depends on their capability to offer regular air conditioning performance, also in settings with high ambient temperatures. This makes them an ideal selection for regions with extreme environments or centers that need a constant cooling tons.

The performance of water-cooled chillers is substantially enhanced by their lower condensing temperature levels, which are enabled by the cooling tower’s ability to dissipate heat better than air-cooled systems. This leads to lower power usage and reduced operational prices, making water-cooled chillers an economical remedy for long-lasting use. In aanvulling, these systems are usually preferred in applications where room is limited, as the air conditioning towers can be installed independently from the refrigerator unit.

Water-cooled chillers are specifically appropriate for applications that require high-capacity air conditioning, such as data facilities, medical facilities, making plants, and huge office buildings. The capability to keep a controlled atmosphere is crucial in these settings, where devices and processes are sensitive to temperature level fluctuations. Bovendien, the usage of water as a cooling medium permits for better adaptability in system style, enabling the modification of refrigerator systems to fulfill details cooling requirements.

In terms of maintenance, water-cooled chillers generally require more attention than air-cooled systems. Routine tracking and upkeep of the air conditioning tower, water therapy to stop scale and rust, and examination of the refrigerator components are vital to make certain optimal efficiency and durability. Regardless of these maintenance needs, the long-lasting benefits in regards to energy financial savings and reliable air conditioning frequently exceed the preliminary investment and recurring upkeep prices.

How do Water Cooled Chillers Work?

Absorption Chillers: How They Differ from Other Types

Water-Cooled Chillers: Efficiency and Applications

Absorption chillers are an one-of-a-kind sort of refrigerator that utilize a different system compared to traditional air-cooled and water-cooled chillers. As opposed to depending on mechanical compression to drive the refrigeration cycle, absorption chillers employ a thermal process including a refrigerant and an absorbing. The most typical mix used is water as the cooling agent and lithium bromide as the absorbing.

Among the essential distinctions is the power source made use of in absorption chillers. They normally harness warmth from resources such as gas, stoom, or hot water, making them an outstanding option in setups where waste warm is readily available or where electrical energy costs are high. This reliance on thermal energy instead of electric power can bring about considerable operational cost savings under the right conditions.

Absorption chillers are likewise recognized for their quiet operation and reduced resonance degrees, as they lack the mechanical compressors located in various other chiller kinds. This makes them suitable for environments where sound and resonance have to be minimized.

| Attribute | Absorption Chillers | Air-Cooled Chillers | Water-Cooled Chillers |

|---|---|---|---|

| Power Source | Thermal (gas, stoom, hot water) | Electrical | Electric |

| Sound and Vibration | Reduced | Medium | Medium |

| Upkeep Complexity | Gematigd | Low | Hoog |

Echter, absorption chillers do feature particular limitations. They usually have a reduced coefficient of performance (Politieagent) contrasted to their electrically driven counterparts, which suggests they are much less efficient in regards to the amount of cooling offered per system of power eaten. In aanvulling, they need a much more complicated maintenance routine as a result of the requirement to handle the absorbing and refrigerant mixture, and to stop formation and deterioration within the system.

Regardless of these obstacles, absorption refrigerators are extremely valued in applications where there is a bountiful supply of waste heat or where electric usage requires to be decreased. They are frequently made use of in commercial setups, large commercial buildings, and areas with cogeneration plants, where their ability to utilize waste heat can be taken full advantage of for better total performance.

Comparison of Air-Cooled and Water-Cooled Chillers

When evaluating the three kinds of chillers, it is necessary to recognize the distinctions between air-cooled and water-cooled chillers. Both have their distinct advantages and appropriate for various applications based on various elements, including environmental conditions, installation room, and effectiveness needs.

Setup and Space Requirements

One of the primary differences in between air-cooled and water-cooled chillers is their setup and area demands. Air-cooled chillers are commonly set up outdoors as a result of their demand for enough air movement to dissipate warm. This makes them ideal for structures with restricted indoor room. In comparison, water-cooled chillers are often installed indoors and require a separate cooling tower, which can enhance the total footprint of the system.

Performance and Performance

In regards to performance, water-cooled chillers usually outshine air-cooled designs. The warmth exchange process in water-cooled chillers is a lot more reliable because water can absorb and move heat better than air. This results in reduced operating expense and higher efficiency, particularly in large applications or environments with constant air conditioning demands. Toch, the greater performance of water-cooled chillers features raised upkeep needs due to the complexity of the system, including the cooling tower, condenser water pumps, and added piping.

Upkeep Considerations

Maintenance is another important aspect where these 2 kinds of chillers vary. Air-cooled chillers are normally less complicated to keep as they have fewer components and do not call for a cooling tower. This simpleness can translate to lower maintenance prices and much less downtime. Aan de andere kant, water-cooled chillers demand routine upkeep of the air conditioning tower, water treatment to stop scaling and corrosion, and regular cleansing of the condenser tubes to maintain performance.

Milieu -impact

Environmental problems likewise play a considerable function in identifying the suitability of each chiller kind. Air-cooled chillers are less impacted by ambient temperatures and can be made use of in a variety of climates. Echter, they tend to be noisier as a result of the followers required for air flow. Water-cooled chillers, while quieter, count on a consistent water supply and are extra at risk to ecological guidelines relating to water use and discharge. Daarom, the selection between air-cooled and water-cooled chillers commonly depends on the certain ecological problems and regulatory demands of the installment site.

Price Implications

The initial cost and operational expenses of these chillers additionally differ considerably. Air-cooled chillers typically have a reduced preliminary price due to the fact that they do not require a cooling tower or complex piping systems. Hoe dan ook, their operating expense can be greater because of much less effective warm transfer. Aan de andere kant, water-cooled chillers, while much more expensive to install, commonly profit from lower operating expenses in time because of their exceptional efficiency. This expense difference must be very carefully reviewed in the context of the particular application and long-lasting usage.

Applications Best Suited for Absorption Chillers

Absorption chillers stand out from various other sorts of refrigerators primarily due to their unique system of procedure, which leverages a warmth source rather than electrical power for refrigeration. This characteristic makes them especially ideal for details applications where waste heat or eco-friendly power resources are readily available.

Industrial Processes

Absorption chillers are extensively made use of in industrial settings where waste warmth is a by-product of manufacturing procedures. Bijvoorbeeld, in chemical plants, refineries, and power generation facilities, these chillers effectively make use of the excess warm to offer air conditioning, thereby boosting total power performance and decreasing operational expenses.

Commercial Buildings

In large commercial structures, such as resorts, healthcare facilities, and workplace complexes, absorption refrigerators are ideal for combined warmth and power (CHP) systems. These systems produce both electrical power and valuable warmth, which the chillers can then make use of to provide cooling. This double use of energy sources dramatically enhances the sustainability and cost-effectiveness of the structure's HVAC system.

Area Cooling Systems

Absorption chillers are a key part in district cooling systems, which disperse cooled water to numerous structures within an area. Such systems frequently integrate cogeneration plants that create electrical power and capture waste warmth for cooling objectives. The combination of absorption chillers in these systems makes sure a stable and reliable cooling supply, reducing ecological effect.

Renewable Energy Integration

Absorption chillers can additionally be powered by sustainable energy resources, such as solar thermal energy. In regions with bountiful sunlight, solar batteries can provide the needed heat to drive the refrigerator, using an eco-friendly cooling remedy. This application is particularly valuable in lowering dependence on fossil fuels and decreasing greenhouse gas exhausts.

Provided their dependence on heat sources, absorption chillers are especially useful in scenarios where waste heat or sustainable power is abundant and where minimizing electric load is a concern. These applications emphasize the adaptability and sustainability of absorption chillers in contemporary energy systems.

Upkeep Tips for Different Types of Chillers

Appropriate maintenance of chillers is necessary for guaranteeing their long-term performance, integrity, en prestaties. De 3 primary types of chillers-- air-cooled, water-cooled, and absorption chillers-- each have details maintenance demands that need to be followed. Listed below, I provide detailed upkeep suggestions tailored per sort of chiller, highlighting the one-of-a-kind elements that ought to be considered to maintain these systems running ideally.

Air-Cooled Chillers

Air-cooled chillers rely on ambient air to dissipate heat, that makes their upkeep somewhat more uncomplicated but still essential. Trick upkeep tasks consist of:

| Task | Frequency |

|---|---|

| Tidy condenser coils to avoid dust and particles accumulation | Month-to-month |

| Check and oil fan motors | Bi-annually |

| Inspect refrigerant degrees and change as needed | Every year |

| Inspect electrical links for wear or corrosion | Yearly |

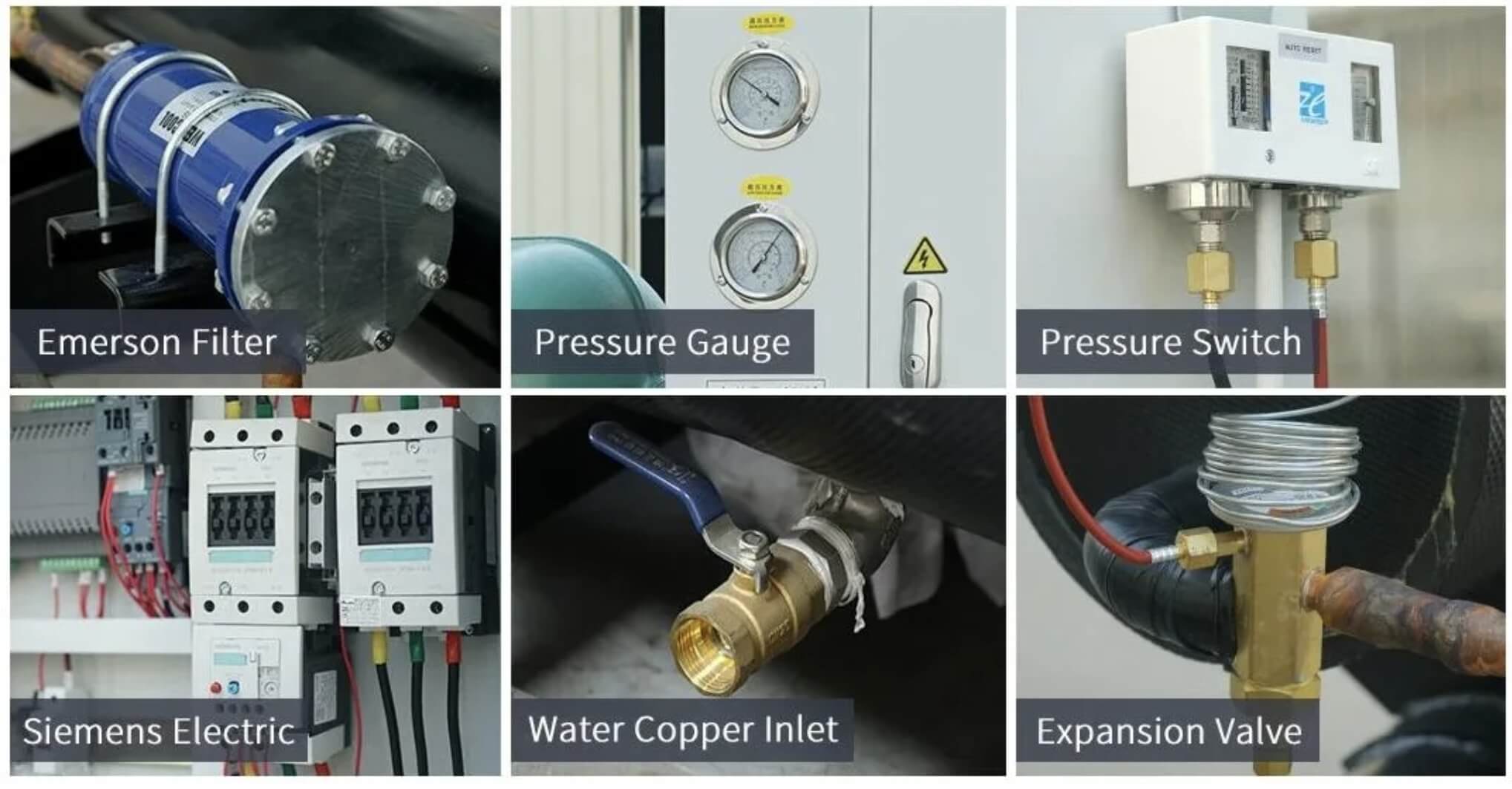

Water-Cooled Chillers

Water-cooled chillers are more effective but call for even more rigorous maintenance due to their complexity. Important upkeep practices consist of:

| Task | Frequency |

|---|---|

| Examine and tidy cooling towers to avoid scaling and organic development | Quarterly |

| Display water top quality and deal with for scale, deterioration, and biological growth | Continually |

| Examination and adjust pressure assesses and sensors | Yearly |

| Inspect and change pump seals and bearings | Each year |

Absorption Chillers

Absorption chillers are unique in their operation, typically utilizing heat sources instead of electrical energy to drive the cooling procedure. Their maintenance involves:

| Task | Frequency |

|---|---|

| Screen and keep the solution concentration | Every year |

| Check and tidy heat exchangers | Annually |

| Look for any type of gas leaks in the system | Bi-annually |

| Routinely evaluate pumps and shutoffs for wear | Annually |

By following these upkeep pointers, facility managers can make certain that their chillers-- whether air-cooled, water-cooled, or absorption-- operate effectively and with marginal downtime. Regular maintenance not just extends the life-span of the devices however additionally improves the general power performance of the system, causing set you back savings over time.

Het bedrijf vóór hem

Wat zijn de drie soorten koelmachines?

Wat zijn de drie soorten koelmachines?

Explores the different types of chillers—air-cooled, water-cooled, En absorption chillers—highlighting their unique features, applications, and maintenance requirements. Air-cooled chillers are praised for their easy installation and low cost, making them ideal for commercial buildings with limited space. Water-cooled chillers, known for their high efficiency, are suitable for larger installations but require more maintenance.

Air-Cooled Chillers: Key Features and Benefits

De air-cooled chillers offer numerous distinct advantages. These systems are especially renowned for their ease of installment and lower initial costs compared to various other sorts of chillers. Air-cooled chillers do not need a separate cooling tower, which simplifies their setup and upkeep. This function alone makes them a perfect choice for installations where water sources are minimal or where extra infrastructure is not possible.

Among the vital benefits of air-cooled chillers is their adaptability. They can be mounted both inside your home and outdoors, offering flexible application in numerous atmospheres. Typisch, air-cooled chillers are used in business buildings, information facilities, and industrial procedures where area goes to a costs. Their compact layout and capability to operate in a wide variety of temperatures further enhance their appeal.

In regards to performance, air-cooled chillers are outfitted with advanced cooling innovations that ensure reliable procedure. Modern devices typically include variable speed drives (VSD) and microchannel condenser coils, which assist to make best use of power performance and reduce operational prices. Aanvullend, these chillers are designed with durable parts that give reputable performance over extended periods, reducing the demand for constant maintenance.

| Attribute | Advantage |

|---|---|

| Ease of Installation | No need for cooling down tower, simpler configuration |

| Flexibility | Can be mounted inside or outdoors |

| Advanced Cooling Technologies | Greater energy performance, reduced operational costs |

| Robust Components | Reliable performance, reduced maintenance |

On the whole, the essential attributes and benefits of air-cooled refrigerators make them a highly appealing choice for numerous applications. Whether handling restrictions associated with room, water availability, or budget, these chillers offer a flexible and economical option for cooling down requirements.

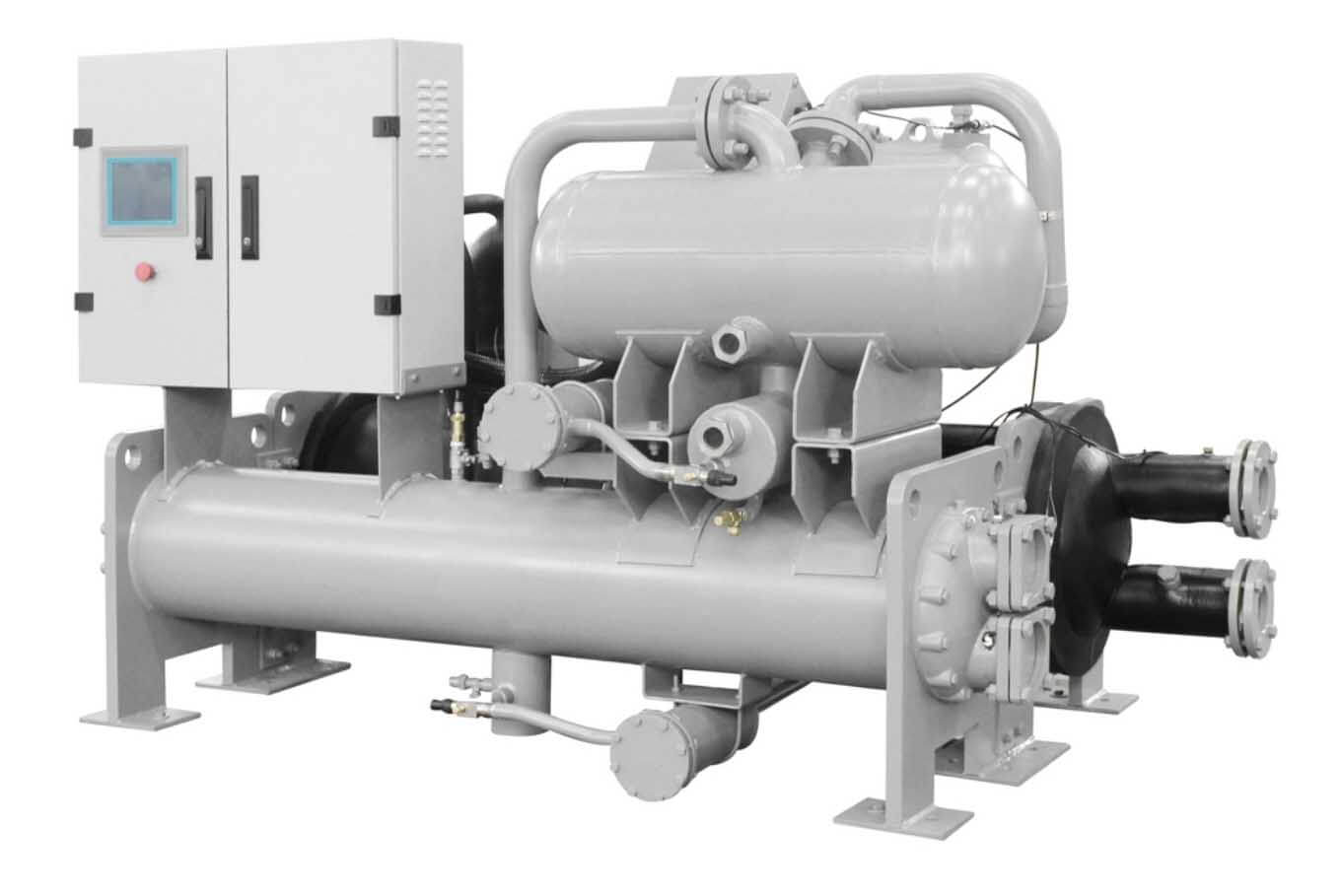

Water-Cooled Chillers: Efficiency and Applications

Water-cooled chillers are known for their high effectiveness and are commonly used in larger commercial and industrial setups. These systems utilize water from an outside air conditioning tower to dissipate warm, making them much more effective than air-cooled chillers in a lot of instances. The primary benefit of water-cooled chillers depends on their capability to offer regular air conditioning performance, also in settings with high ambient temperatures. This makes them an ideal selection for regions with extreme environments or centers that need a constant cooling tons.

The performance of water-cooled chillers is substantially enhanced by their lower condensing temperature levels, which are enabled by the cooling tower’s ability to dissipate heat better than air-cooled systems. This leads to lower power usage and reduced operational prices, making water-cooled chillers an economical remedy for long-lasting use. In aanvulling, these systems are usually preferred in applications where room is limited, as the air conditioning towers can be installed independently from the refrigerator unit.

Water-cooled chillers are specifically appropriate for applications that require high-capacity air conditioning, such as data facilities, medical facilities, making plants, and huge office buildings. The capability to keep a controlled atmosphere is crucial in these settings, where devices and processes are sensitive to temperature level fluctuations. Bovendien, the usage of water as a cooling medium permits for better adaptability in system style, enabling the modification of refrigerator systems to fulfill details cooling requirements.

In terms of maintenance, water-cooled chillers generally require more attention than air-cooled systems. Routine tracking and upkeep of the air conditioning tower, water therapy to stop scale and rust, and examination of the refrigerator components are vital to make certain optimal efficiency and durability. Regardless of these maintenance needs, the long-lasting benefits in regards to energy financial savings and reliable air conditioning frequently exceed the preliminary investment and recurring upkeep prices.

How do Water Cooled Chillers Work?

Absorption Chillers: How They Differ from Other Types

Water-Cooled Chillers: Efficiency and Applications

Absorption chillers are an one-of-a-kind sort of refrigerator that utilize a different system compared to traditional air-cooled and water-cooled chillers. As opposed to depending on mechanical compression to drive the refrigeration cycle, absorption chillers employ a thermal process including a refrigerant and an absorbing. The most typical mix used is water as the cooling agent and lithium bromide as the absorbing.

Among the essential distinctions is the power source made use of in absorption chillers. They normally harness warmth from resources such as gas, stoom, or hot water, making them an outstanding option in setups where waste warm is readily available or where electrical energy costs are high. This reliance on thermal energy instead of electric power can bring about considerable operational cost savings under the right conditions.

Absorption chillers are likewise recognized for their quiet operation and reduced resonance degrees, as they lack the mechanical compressors located in various other chiller kinds. This makes them suitable for environments where sound and resonance have to be minimized.

| Attribute | Absorption Chillers | Air-Cooled Chillers | Water-Cooled Chillers |

|---|---|---|---|

| Power Source | Thermal (gas, stoom, hot water) | Electrical | Electric |

| Sound and Vibration | Reduced | Medium | Medium |

| Upkeep Complexity | Gematigd | Low | Hoog |

Echter, absorption chillers do feature particular limitations. They usually have a reduced coefficient of performance (Politieagent) contrasted to their electrically driven counterparts, which suggests they are much less efficient in regards to the amount of cooling offered per system of power eaten. In aanvulling, they need a much more complicated maintenance routine as a result of the requirement to handle the absorbing and refrigerant mixture, and to stop formation and deterioration within the system.

Regardless of these obstacles, absorption refrigerators are extremely valued in applications where there is a bountiful supply of waste heat or where electric usage requires to be decreased. They are frequently made use of in commercial setups, large commercial buildings, and areas with cogeneration plants, where their ability to utilize waste heat can be taken full advantage of for better total performance.

Comparison of Air-Cooled and Water-Cooled Chillers

When evaluating the three kinds of chillers, it is necessary to recognize the distinctions between air-cooled and water-cooled chillers. Both have their distinct advantages and appropriate for various applications based on various elements, including environmental conditions, installation room, and effectiveness needs.

Setup and Space Requirements

One of the primary differences in between air-cooled and water-cooled chillers is their setup and area demands. Air-cooled chillers are commonly set up outdoors as a result of their demand for enough air movement to dissipate warm. This makes them ideal for structures with restricted indoor room. In comparison, water-cooled chillers are often installed indoors and require a separate cooling tower, which can enhance the total footprint of the system.

Performance and Performance

In regards to performance, water-cooled chillers usually outshine air-cooled designs. The warmth exchange process in water-cooled chillers is a lot more reliable because water can absorb and move heat better than air. This results in reduced operating expense and higher efficiency, particularly in large applications or environments with constant air conditioning demands. Toch, the greater performance of water-cooled chillers features raised upkeep needs due to the complexity of the system, including the cooling tower, condenser water pumps, and added piping.

Upkeep Considerations

Maintenance is another important aspect where these 2 kinds of chillers vary. Air-cooled chillers are normally less complicated to keep as they have fewer components and do not call for a cooling tower. This simpleness can translate to lower maintenance prices and much less downtime. Aan de andere kant, water-cooled chillers demand routine upkeep of the air conditioning tower, water treatment to stop scaling and corrosion, and regular cleansing of the condenser tubes to maintain performance.

Milieu -impact

Environmental problems likewise play a considerable function in identifying the suitability of each chiller kind. Air-cooled chillers are less impacted by ambient temperatures and can be made use of in a variety of climates. Echter, they tend to be noisier as a result of the followers required for air flow. Water-cooled chillers, while quieter, count on a consistent water supply and are extra at risk to ecological guidelines relating to water use and discharge. Daarom, the selection between air-cooled and water-cooled chillers commonly depends on the certain ecological problems and regulatory demands of the installment site.

Price Implications

The initial cost and operational expenses of these chillers additionally differ considerably. Air-cooled chillers typically have a reduced preliminary price due to the fact that they do not require a cooling tower or complex piping systems. Hoe dan ook, their operating expense can be greater because of much less effective warm transfer. Aan de andere kant, water-cooled chillers, while much more expensive to install, commonly profit from lower operating expenses in time because of their exceptional efficiency. This expense difference must be very carefully reviewed in the context of the particular application and long-lasting usage.

Applications Best Suited for Absorption Chillers

Absorption chillers stand out from various other sorts of refrigerators primarily due to their unique system of procedure, which leverages a warmth source rather than electrical power for refrigeration. This characteristic makes them especially ideal for details applications where waste heat or eco-friendly power resources are readily available.

Industrial Processes

Absorption chillers are extensively made use of in industrial settings where waste warmth is a by-product of manufacturing procedures. Bijvoorbeeld, in chemical plants, refineries, and power generation facilities, these chillers effectively make use of the excess warm to offer air conditioning, thereby boosting total power performance and decreasing operational expenses.

Commercial Buildings

In large commercial structures, such as resorts, healthcare facilities, and workplace complexes, absorption refrigerators are ideal for combined warmth and power (CHP) systems. These systems produce both electrical power and valuable warmth, which the chillers can then make use of to provide cooling. This double use of energy sources dramatically enhances the sustainability and cost-effectiveness of the structure's HVAC system.

Area Cooling Systems

Absorption chillers are a key part in district cooling systems, which disperse cooled water to numerous structures within an area. Such systems frequently integrate cogeneration plants that create electrical power and capture waste warmth for cooling objectives. The combination of absorption chillers in these systems makes sure a stable and reliable cooling supply, reducing ecological effect.

Renewable Energy Integration

Absorption chillers can additionally be powered by sustainable energy resources, such as solar thermal energy. In regions with bountiful sunlight, solar batteries can provide the needed heat to drive the refrigerator, using an eco-friendly cooling remedy. This application is particularly valuable in lowering dependence on fossil fuels and decreasing greenhouse gas exhausts.

Provided their dependence on heat sources, absorption chillers are especially useful in scenarios where waste heat or sustainable power is abundant and where minimizing electric load is a concern. These applications emphasize the adaptability and sustainability of absorption chillers in contemporary energy systems.

Upkeep Tips for Different Types of Chillers

Appropriate maintenance of chillers is necessary for guaranteeing their long-term performance, integrity, en prestaties. De 3 primary types of chillers-- air-cooled, water-cooled, and absorption chillers-- each have details maintenance demands that need to be followed. Listed below, I provide detailed upkeep suggestions tailored per sort of chiller, highlighting the one-of-a-kind elements that ought to be considered to maintain these systems running ideally.

Air-Cooled Chillers

Air-cooled chillers rely on ambient air to dissipate heat, that makes their upkeep somewhat more uncomplicated but still essential. Trick upkeep tasks consist of:

| Task | Frequency |

|---|---|

| Tidy condenser coils to avoid dust and particles accumulation | Month-to-month |

| Check and oil fan motors | Bi-annually |

| Inspect refrigerant degrees and change as needed | Every year |

| Inspect electrical links for wear or corrosion | Yearly |

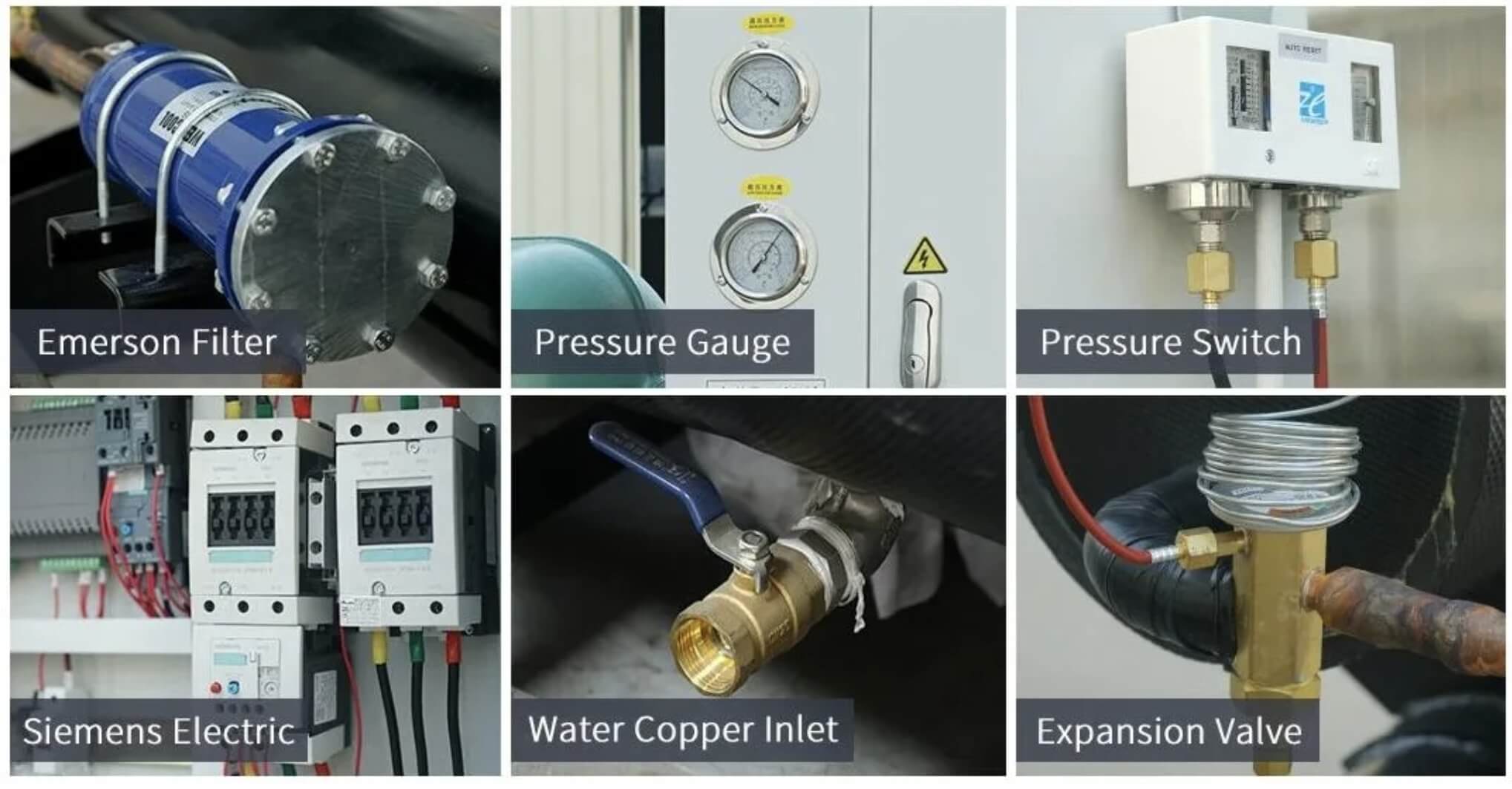

Water-Cooled Chillers

Water-cooled chillers are more effective but call for even more rigorous maintenance due to their complexity. Important upkeep practices consist of:

| Task | Frequency |

|---|---|

| Examine and tidy cooling towers to avoid scaling and organic development | Quarterly |

| Display water top quality and deal with for scale, deterioration, and biological growth | Continually |

| Examination and adjust pressure assesses and sensors | Yearly |

| Inspect and change pump seals and bearings | Each year |

Absorption Chillers

Absorption chillers are unique in their operation, typically utilizing heat sources instead of electrical energy to drive the cooling procedure. Their maintenance involves:

| Task | Frequency |

|---|---|

| Screen and keep the solution concentration | Every year |

| Check and tidy heat exchangers | Annually |

| Look for any type of gas leaks in the system | Bi-annually |

| Routinely evaluate pumps and shutoffs for wear | Annually |

By following these upkeep pointers, facility managers can make certain that their chillers-- whether air-cooled, water-cooled, or absorption-- operate effectively and with marginal downtime. Regular maintenance not just extends the life-span of the devices however additionally improves the general power performance of the system, causing set you back savings over time.

Over hun auteur

Welkom op onze blog! Mijn naam is Peter en ik ben de hoofdauteur van deze blog. Als sportherstelbeoefenaar en met diepe interesses en expertise.

Ik streef ernaar om complexe concepten op een heldere en bondige manier te presenteren, en lezers in staat stellen die kennis beter te begrijpen en toe te passen door middel van diepgaand onderzoek en het delen van ervaringen.

Bedankt voor het lezen en voor uw steun! Als u vragen of suggesties heeft over de inhoud, Neem dan gerust contact met mij op. Ik kijk ernaar uit om meer interessante en nuttige informatie met u te delen en samen te groeien op deze kennisreis!